Join MRAC community

INTRODUCTION

IAAC’s Master in Robotics and Advanced Construction (1 or 2-year program) seeks to train a new generation of interdisciplinary professionals, capable of facing our growing need for a more sustainable and optimized construction eco-system. The Master is focused on the emerging design and market opportunities arising from novel robotic and advanced manufacturing systems.

Through a mixture of seminars, workshops and studio projects, the Master in Robotics & Advanced Construction challenges the traditional processes in the Construction Sector. It investigates how advances in robotics and digital fabrication tools change the way we build and develop processes and design tools for such new production methods.

The 3rd Application Period for the academic year 2024/25 is now open until the 30th of April 2024!

MRAC 01 |

MRAC 01 + 3DPA |

MRAC 02 |

|

| Degree | Master in Robotics and Advanced Construction I accredited by University of Lleida (UdL) – European Higher Education Area (EHEA) | Master in Robotics and Advanced Construction + Postgraduate Diploma in 3D Printing Architecture. Both accredited by by University of Lleida (UdL) – European Higher Education Area (EHEA) | Master in Robotics and Advanced Construction II accredited by by University of Lleida (UdL) – European Higher Education Area (EHEA) |

| Edition | 6th edition | 5th edition | 3rd edition |

| Credits | 90 ECTS | 90 ECTS (MRAC) + 45 ECTS (3DPA) | 120 ECTS |

| Duration | October 2024 to July 2025 // Full Time (10 months) | October 2024 to March 2026 // Full Time (15 months) | October 2024 to July 2026 // Full Time (20 months) |

| Language | English | English | English |

| Tuition Fee | Non-EU: 23.850€ EU: 19.800€ Spanish: 11.925€ |

Non-EU: 32.197€ EU: 26.730€ Spanish: 16.100€ |

Non-EU: 31.800€ EU: 26.400€ Spanish: 15.900€ |

| Admission | Bachelor degree or a higher degree in Architecture, Engineering or other related fields | Bachelor degree or a higher degree in Architecture, Engineering or other related fields | Bachelor degree or a higher degree in Architecture, Engineering or other related fields |

* Tuition fee includes a non-refundable programme enrollment fee of 3.800€

**Transportation to any of the IAAC Campus and other services not mentioned are not included.

CONTEXT & AGENDA

The construction sector is currently faced with a need for change.Growing cities are challenging the sector to find better ways to build more and at a lower cost. Furthermore, the limited resources that we have on this planet push us towards a more sustainable way of building, inhabiting, and reusing our construction materials and waste. On top of this, an aberration from mass-produced cities indicates a need for a more holistic design, integrating the various needs and desires of the inhabitants.

In this context, the Master in Robotics & Advanced Construction proposes a new interdisciplinary programme, connecting its students with exceptional international practitioners, industries, institutions and collaborative entities. The students will learn about the state of the art in Robotics and, as well as theory and practical tools of computational design and artificial intelligence. They will become fluent in the use of these technologies through continuous hands-on experiments, methodology, and a series of workshops and pilot projects with research and industry partners.

Materialising with Machines

First Term

Scanning and Learning Machines

Second Term

Human-Machine Collaboration

Third Term

TOOLS & SOFTWARE

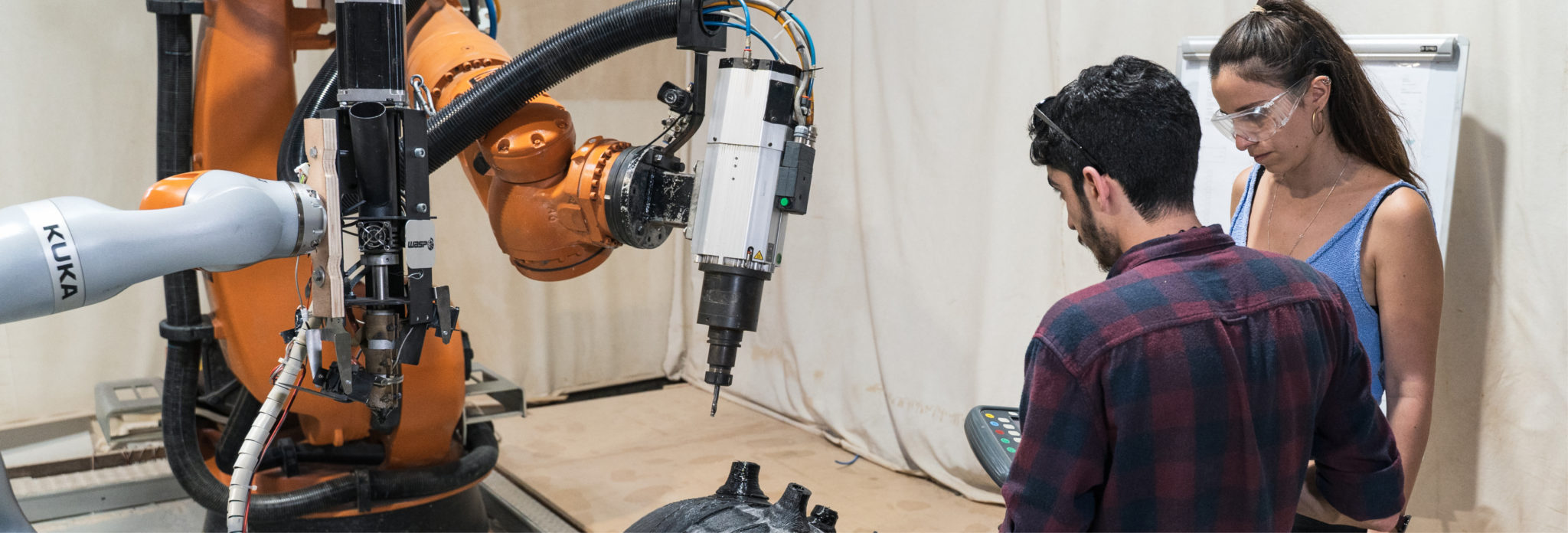

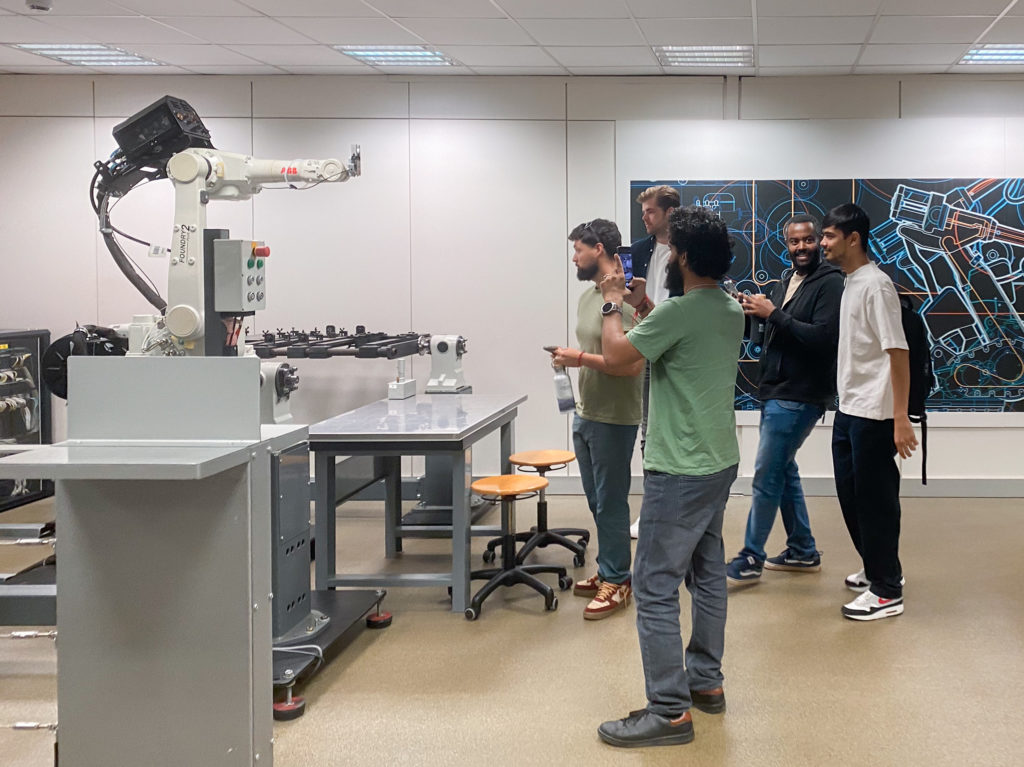

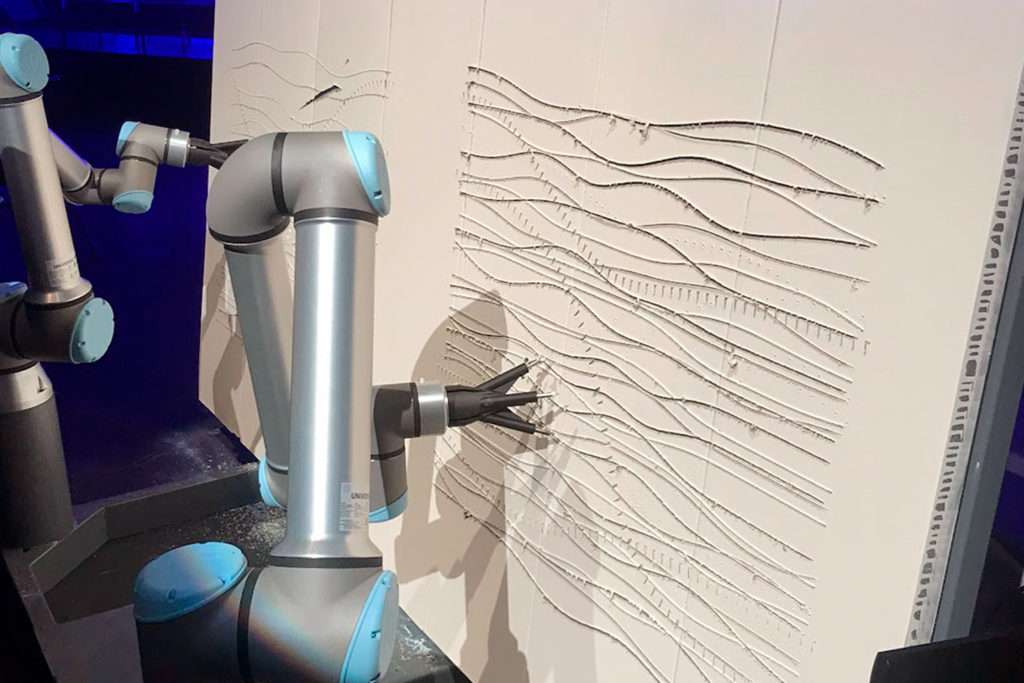

Students of the Master in Robotics & Advanced Construction are introduced to a large variety of technological tools and software that are essential for the robotic optimisation of the construction industry. During the programme, students are trained on the latest tools for digital fabrication, computational design, robotic simulation, hardware design, programming and electronics. Finally, the students will also become experts in working with KUKA, ABB and UR robots.

Seminars, studios and workshops on the following tools and software are conducted:

PREVIOUS PROJECTS

ACADEMIC STRUCTURE

The Master in Robotics and Advanced Construction offers students the possibility of pursuing the programme in 4 different modalities: MRAC01, MRAC01+3DPA and MRAC02.

During the programme, students will be part of a highly international group of faculty members, researchers and lecturers, encouraging them to develop collective decision-making processes and materialize their project ideas through a series of seminars, studios and hands-on workshops. In this way, IAAC puts together an experimental learning environment for the training of professionals with both theoretical and practical responses to the increasing complexity of the construction sector.

MASTER IN ROBOTICS & ADVANCED CONSTRUCTION (1-Year Program) // Full-Time

The first year of the Master in Robotics & Advanced Construction comprises the following elements:

- Design Research Studios

- Software Seminars

- Hardware Seminars

- Workshops

- Theory & Context Seminars

- Industry Visits

DESIGN STUDIO AND SEMINARS

Advances in File to Factory workflow allows for precise and complex constructions. In this new paradigm, the architecture will be mass customised, constructive logic will be encoded, new materials will be introduced and materiality will be programmed.

During this first term, students will explore the possibilities being already offered by digital fabrication and computational design to gain control over the entire process of materialisation from digital to physical, from the human intention to the robot execution. A special focus will be given on the challenges and opportunities raised by Robotic and Additive Manufacturing for construction.

TERM 1 COURSES:

- Design Research Studio – Robotic Craft (10 ECTS)

- Software Seminar – Algorithmic Design (3 ECTS)

- Hardware Seminar – Robotic Actuators (3 ECTS)

- Workshop – Additive Manufacturing (3 ECTS)

- Workshop – Subtractive Manufacturing (3 ECTS)

- Theory & Context Seminar – Materialising with Machines (3 ECTS)

NOTE: Design Studio, Seminars and Workshops of Term 1 are obligatory.

DESIGN STUDIO AND SEMINARS

Advances in data collection (sensors, drones, …) and analysis (optimisation algorithm, AI, …) allows for better integration of the construction specific challenges such as site monitoring and adaptability, heterogeneous materials, inventory management, assembly tolerances, changing climate conditions and team coordination.

During the second semester, students will integrate increasing amounts of data in their workflow, using robotic sensing and digital simulation to get new information of the construction process. Physical computing and analytics will help drive new decision making processes including iterative logics, computational optimisation and artificial intelligence.

TERM 2 COURSES:

- Design Research Studio – Robotic Sensing (10 ECTS)

- Software Seminar – Robotic Control (3 ECTS)

- Hardware Seminar – Robotic Sensors (3 ECTS)

- Workshop – 3D Scanning in Construction (3 ECTS)

- Workshop – Adaptive Fabrication (3 ECTS)

- Theory & Context Seminar – Scanning and Learning Machines (3 ECTS)

NOTE: Design Studio, Seminars and Workshops of Term 2 are obligatory.

DESIGN STUDIO AND SEMINARS

Advances in Human-Machine Interactions and mixed realities allows for a seamless collaboration between humans and robots in factory and construction sites, taking advantages of the best of both virtual and real world.

During the third semester, students will extend their skills and perspectives towards new devices and strategies that combine existing manual constructive methods with the digital and robotic ones. This new digital craftsmanship in factories and construction sites will be the scenario students will use to explore the potential of collaborative robots and Augmented Reality for the construction sector.

TERM 3 COURSES:

- Design Research Studio – Final Project (10 ECTS)

- Software Seminar – Machine Learning (3 ECTS)

- Hardware Seminar – Robotic Interaction (3 ECTS)

- Workshop – Collaborative Robotics (3 ECTS)

- Workshop – Swarm Robotics (3 ECTS)

- Theory & Context Seminar – Human – Machine collaboration (3 ECTS)

NOTE: Design Studio, Seminars and Workshops of Term 3 are obligatory

MASTER IN ROBOTICS & ADVANCED CONSTRUCTION Full-Time + POSTGRADUATE IN 3D PRINTING ARCHITECTURE

The Master in Robotics and Advanced Construction first year can be combined with the complementary programme 3DPA. This allows students to apply the knowledge learnt into this unique applied research program center into the revolutionising technology of additive manufacturing for the construction of sustainable architecture.

For more information on 3DPA, please visit the programme’s page here.

MASTER IN ROBOTICS & ADVANCED CONSTRUCTION + THESIS PROJECT (2-Year Program)

Master in Robotics & Advanced Construction + Thesis Project – FIRST YEAR

The first year of the Master in Robotics & Advanced Construction + Thesis Project is the same for both programmes and has a structure of 3 terms of 3 months each.

Master in Robotics & Advanced Construction + Thesis Project – SECOND YEAR

Targeted towards students’ future career in Academia, Start-up or Industry, the second year of the Master in Robotics and Advanced Construction offers the occasion to develop a thesis project with the support of IAAC infrastructure, experts and network, with the goal to maximise its impact on our society.

Students can choose to work either individually or in a group, and can propose their own topic and collaborative company, or choose from the one proposed by IAAC and its strong partners. The development of the project will be supported by advanced seminars in Technology, Theory and Business to bring the proposal state of the art research that can really impact the construction industry. To this end, students will collaborate with one specific industry / academia or incubator to develop their project, with a series of internship immersion in the collaborative company as well as review and support directly on the thesis project.

In parallel to the development of the Thesis Project Studio, the second year of the Master in Robotics and Advanced Construction offers a series of seminars enhancing both the theoretical, practical and digital skills of the students. Students will also have the occasion to join cross-disciplinary workshops to build large prototypes and installations.

The Second Academic year of the Master in Robotics & Advanced Construction comprises the following elements:

- Thesis Research Studio

- Technical Support

- Workshops

- Theory Seminars

- Cross-Reviews

- Internship at Collaborative Industry / Academia / Incubator

The programme is organized into three terms.

Throughout all three terms, the Master in Robotics & Advanced Construction + Thesis Project students will attend transversal sessions which bring them in direct contact with their thesis advisor(s) as well as front running professionals in the fields of robotics, construction, economics, and sustainability. All classes throughout all the terms are mandatory.

- Thesis Research Studio – Academy & Start-Up Oriented Thesis (27 ECTS)

- Technical Support – Advanced Technology (2 ECTS)

- Theory Seminar – Research & Methods (3 ECTS)

- Cross-Reviews – Thesis Cross-Reviews (3 ECTS)

- Internship at Collaborative Industry / Academia / Incubator (4 ECTS)

In parallel to the Thesis Research Studio sessions and the Theory Seminars, the first term consists of the following courses:

TERM 1 COURSES:

- Workshop – Cross-Disciplinary Project (3 ECTS)

- Theory – Economics of Sustainability & Impact (1 ECTS)

In parallel to the Thesis Research Studio sessions and the Theory Seminars, the second term consists of the following courses:

TERM 2 COURSES:

- Workshop – Cross-Disciplinary Prototype (3 ECTS)

- Theory – Business Innovation (1 ECTS)

In parallel to the Thesis Research Studio sessions and the Theory Seminars, the third term consists of the following courses:

TERM 3 COURSES:

- Theory – Market for Industry Research (1 ECTS)

STUDENT PROFILE

The Master in Robotics & Advanced Construction is designed for architects, engineers, designers and craftsmen/craftswomen who are interested in sustainable construction and are willing to challenge the boundaries of robotics and advanced manufacturing.

If you are passionate about manipulating and integrating robotics and advanced manufacturing processes, creating parametric design for mass customisation, integrating computer vision and sensor feedback for complex material systems and fabrication processed, exploring the potential of computational optimisation using artificial intelligence, understanding the potential of autonomous robot systems, developing new applications of augmented reality, proposing new digital design and building technologies, then the Master in Robotics & Advanced Construction is made for you.

PROFESSIONAL OPPORTUNITIES

After completing the Master degree, IAAC alumni will have the opportunity to either join renown companies (Zaha Hadid, Foster, BIG), continue their research in other institutions or centers (MIT, ETH Zurich, Eurecat, AA school) or launch their own practice and start-up (Scaled Robotics, DesignandRobotics and more). By choosing to apply for the 2 year programme, students will get in closer contact with IAAC partner industries, universities and start-up incubators, taking full advantage of IAAC’s network to create their future career. See below some of the IAAC alumni stories and discover what they have to say about their careers!

Anna Batallé – Researcher at Eurecat

Master in Robotics & Advanced Construction 2019/20 Alumna

Stuart Maggs – CEO at Scaled Robotics

Master in Advanced Architecture 2012/13 Alumnus

INDUSTRY PARTNERS

PROGRAMME DIRECTORS

Aldo Sollazzo is an Italian entrepreneur and innovator, expert in robotics, computer vision, and computational design. He is the CEO of Noumena since 2011, a data-driven company implementing computer vision and machine learning to study and analyze spatial dynamics.

As part of the Noumena Group, he is also the CEO of Reshape, a platform focused on the industrial application of material-driven sustainable technologies, and of LAMÁQUINA, a large-scale 3D printing factory, shaping new architectural solutions integrating advanced manufacturing and computation.

In 2019 Aldo received, from the Italian President of the Republic, the title of Knight of the Order of the Star of Italy for the promotion of national prestige abroad as a recognition of his scientific and technological activities.

Aldo has made many appearances as a guest speaker at Conferences and University Seminars, amongst them European Conference on Computer Vision, Barcelona Urban Tech, Future City Summit, The Venice Biennale and TEDx Barcelona.

Alexandre Dubor is an architect and researcher combining new technologies in an attempt to improve how we build and live in our cities. He holds a Master degree of Architecture & Engineering from EAVT & ENPC (France) and a Master Degree of Architecture from IAAC (Spain), with a specialisation in robotic fabrication and large scale additive manufacturing (FabBot 3.0).

He holds as well a French architectural licence (HMONP) and have worked in various architectural office from competition stage to delivery (Libeskind, Atenastudio, iDonati, AREP) while exploring the potential of scripting and coding in a separate practice (Collectif277). Since 2012, he has been working at IAAC as an expert in digital and robotic fabrication. He is now leading the AAG Fabrication team, and co-direct the postgraduate in 3D Printing Architecture (3DPA) as well as the Master in Robotic and Advanced Construction (MRAC).

Together with IAAC staff, students and industrial partners, he is investigating how new advances in material, digital fabrication and computational design could lead to a better construction ecosystem, toward a more efficient, affordable, sustainable and personalised built environment.