The system can work with other species of plants and algae, nevertheless, moss was chosen because of its eligible properties. As mosses are commonly found in cities, in cracks between paving, on roofs, on walls and trees, the system can be well adapted to the urban environment. Advantages of mosses over higher plants include reduced weight loads, increased water absorption, no fertilizer requirements, high drought tolerance and low maintenance.

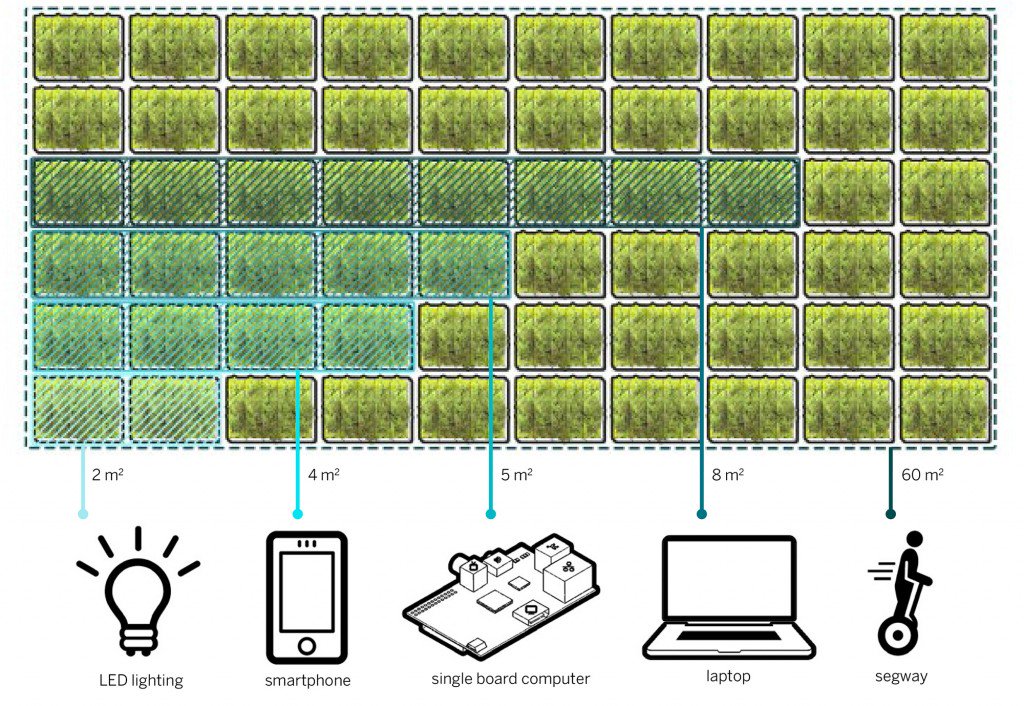

Compared with silicon-based photovoltaic cells, a solar cell that uses biological material to capture light energy would be cheaper to produce, self-repairing, self-replicating, biodegradable and much more sustainable. The manufacturing process is harmless to the environment. Furthermore, BPV panels can exist in the places where solar panels are not efficient – northern countries with the lack of direct sunlight for example.

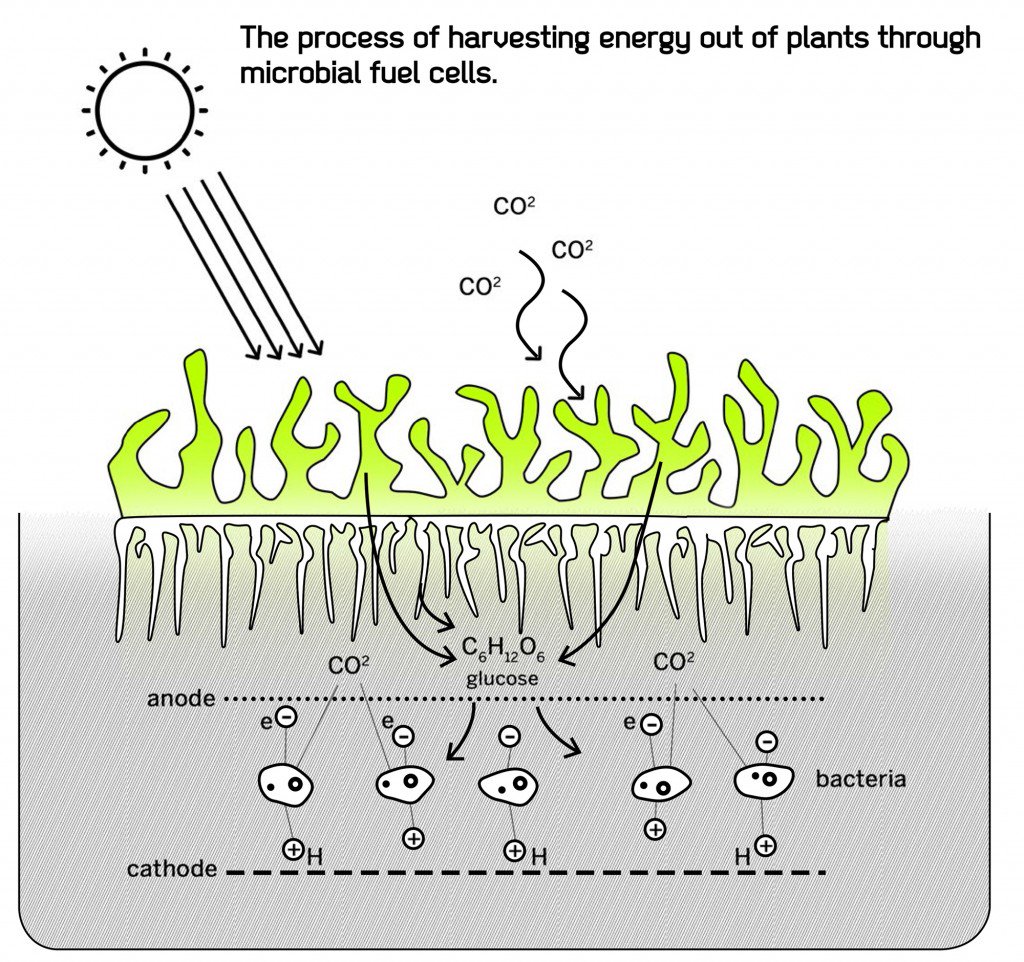

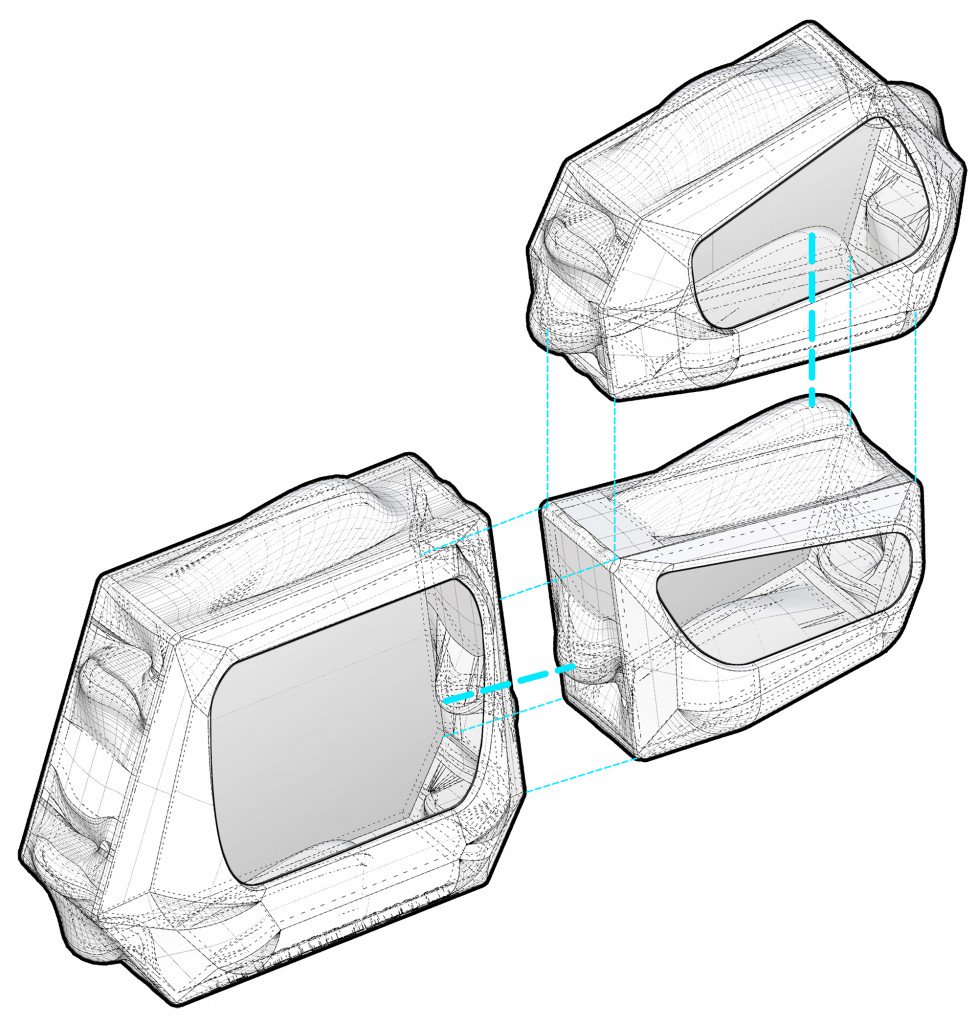

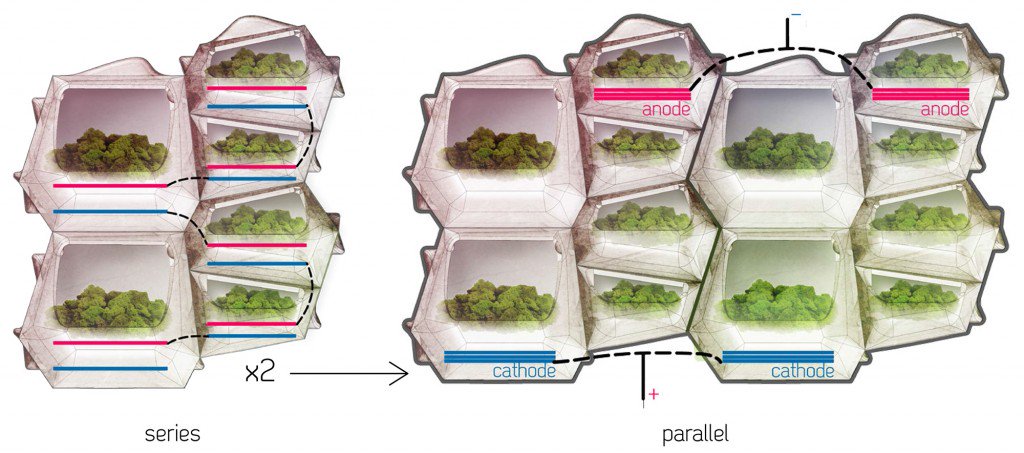

A biophotovoltaic cell represents an organisation of units combined in series or parallel circuits. A unit is a fully operating bio-electrical system. It consists of the anodic biological material (moss), the anode, the cathode, the cathodic catalyst, the “salt bridge” that permit the positive charge (generally protons) to travel from the anodic biological material to the cathode. The anode represents the mixture of hydrogel and carbon fibres that help to attract the electrons. A hydrogel is a polymer that can absorb water up to 400 times to its weight, it keeps complementary humidity for the moss and it is pH neutral.

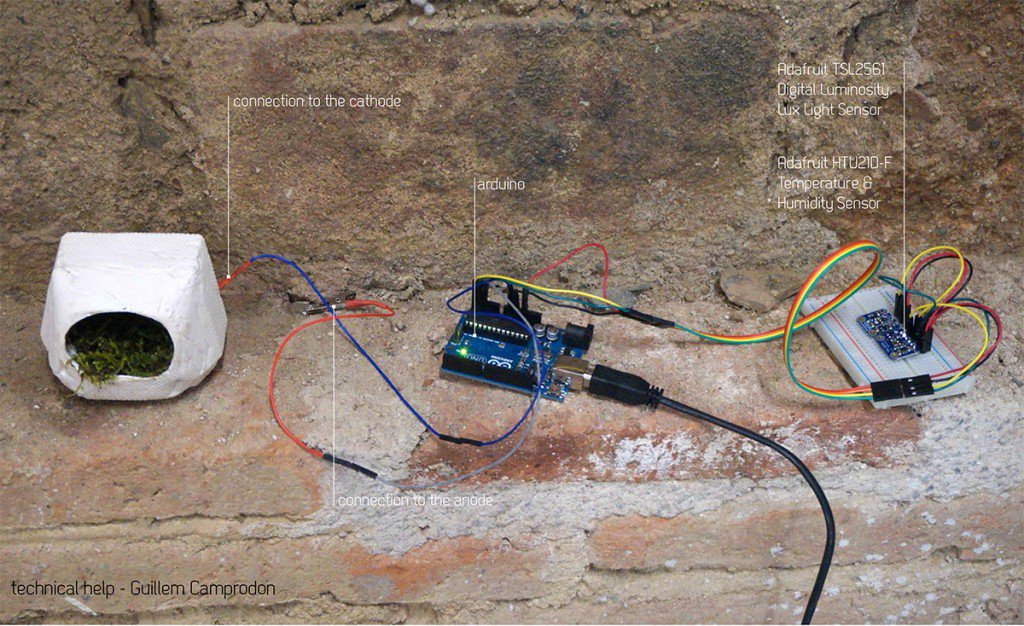

The materials are not damaging any metabolism, thus the first tests to check how the fibres coexist with moss and polyacrylate were made. One unit 100x100mm for the anode was mixed carbon fibres and hydrogel in cubes (sliced for thinner, smaller sheets) and a layer of carbon fabric, the mixture was covered with moss. The cell showed 0,35 volts. Meanwhile, “moss plantation” was set up wherefrom anode would be taken for embedding into the structure. For this, fibres with polyacrylate were mixed and moss was placed atop and pressed down plus, the moss was divided into small pieces and distributed over the same mixture. After 1 month, moss grew through the mixture of carbon fibre and hydrogel.