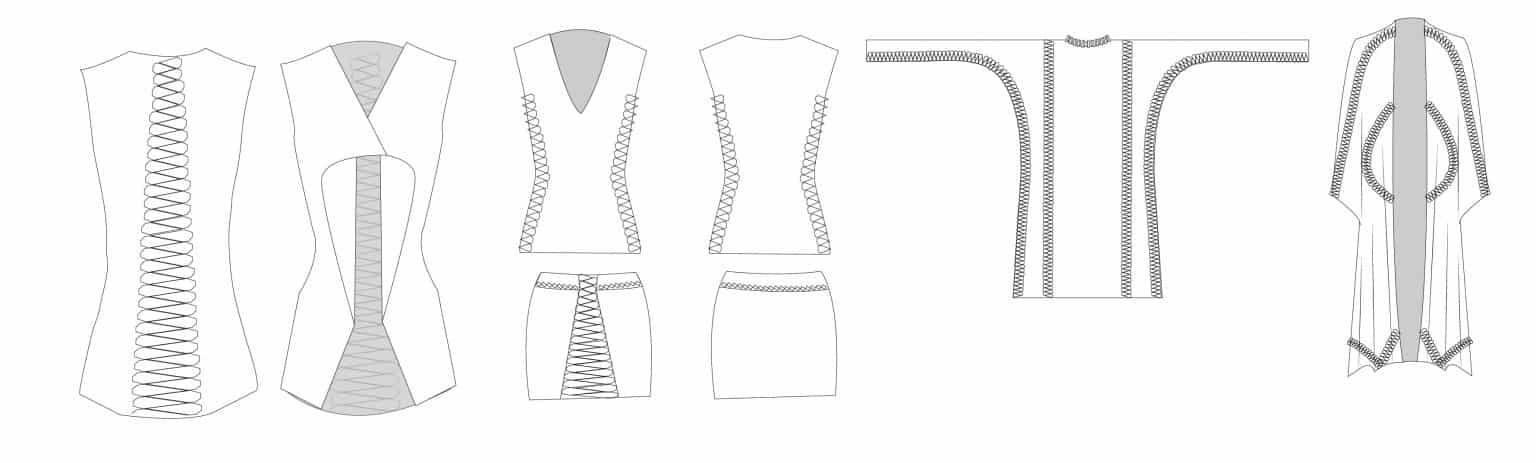

The digital fabrication jacket uses a variety of digital and analogue tools including digital computing and fabrication methods which meant that we were able to rapidly prototype and assemble the new designs. You can use any 2D or 3D software to create patterns which are ready for cutting.

The machines allow us a wide range of possibilities, so try to take advantage of the accuracy, precision and repetitions these machines can achieve. If you don’t have them, these tools can be found at your local Fab Lab shop or digital fabrication laboratory (if you don’t have them at home, and aside from the laser cutter, you probably will) book a time slot for fabrication with your local Fab Lab or tech shop.